The feed material is typically below 2 mm and moisture below 2. Cleaning and maintenance of the PPS Air Classifier Mill system is enhanced by.

Operate An Air Classifier Mill To Meet Your Fine Grinding Goals Hosokawa Micron Powder Systems

The grinding media is typically steel or ceramic in the range of one to eight millimeters.

. The PPS Air Classifier Mills also have a versatile. Speed of wheel is controlled by inventer particle size can be adjusted freely. RSG Inc located in Sylacauga Alabama USA.

Outboard bearings for ease of maintenance. Here is our complete guide with everything you need to know about purchasing an air classification system. Air Classifiers AC Three types of separators each with a high-precision method of classifying particles according to size or density.

Launched by Hosokawa in 1962 the original ACM Air Classifier Mill was the first mill of its type available and it continues to be a very popular choice with customers from many sectors. Characteristic for the ACM is the integrated dynamic classifier. Air Classifier Design - China Manufacturers Factory Suppliers.

Ad Get Air Classifier Mills Parts Within 24 Hours Or Consult With Industry Experts. Page 1 Air classifiers eliminate the blinding and breakage issues associated with screens. For dry materials of 100-mesh and smaller air classification provides the most.

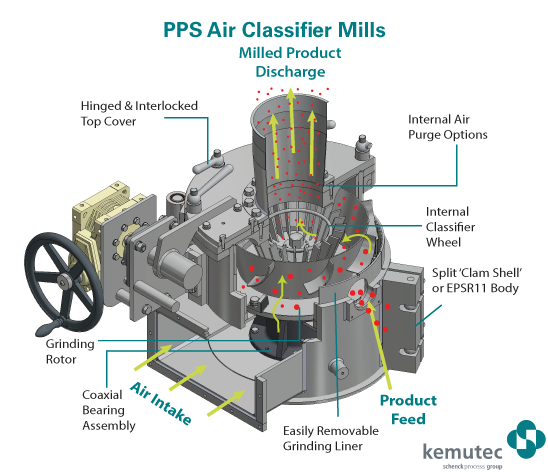

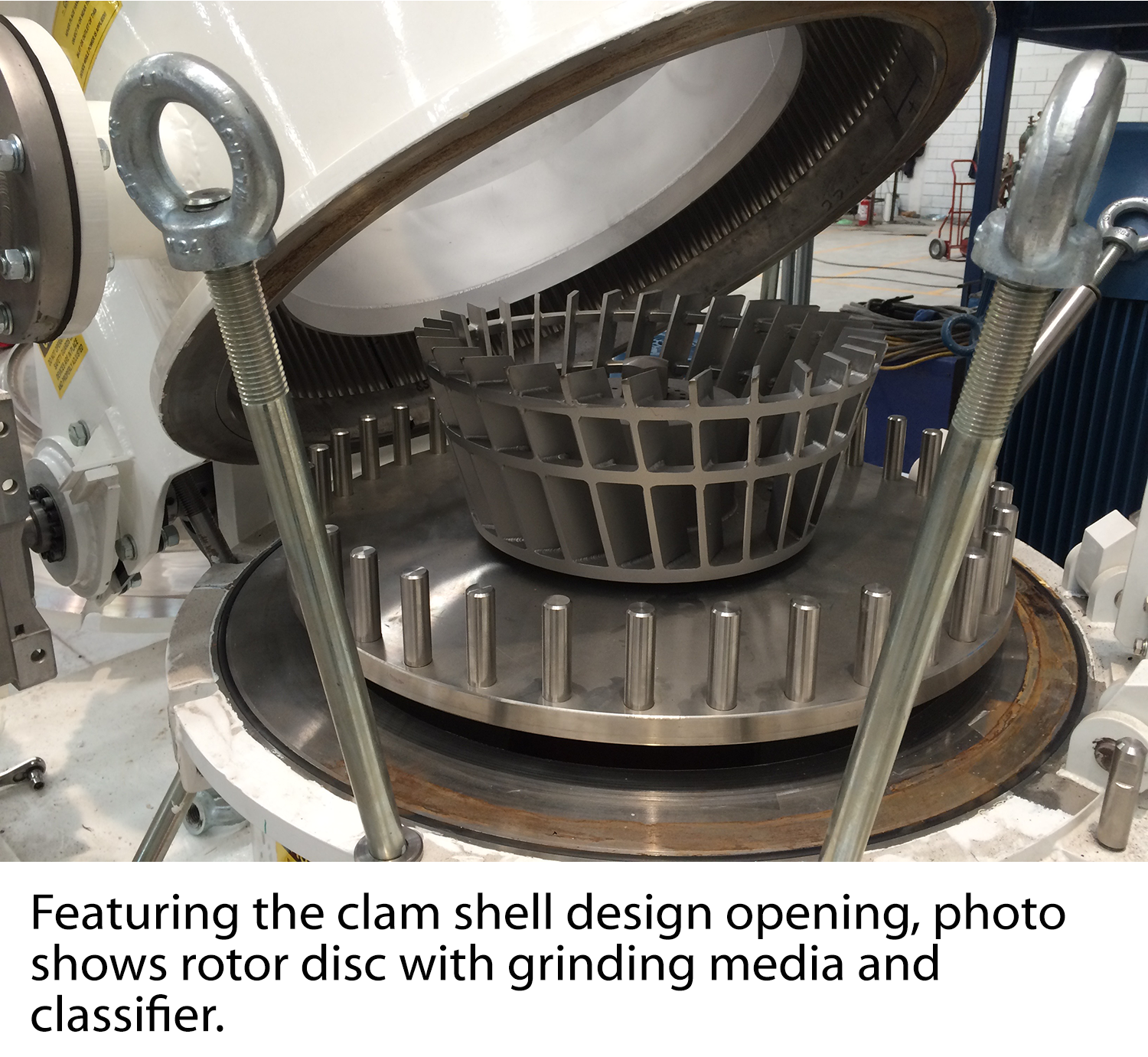

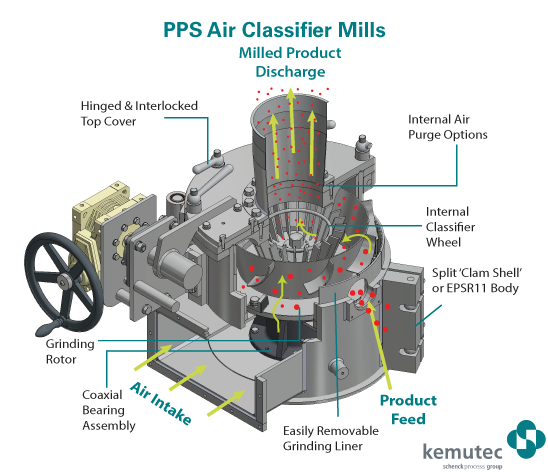

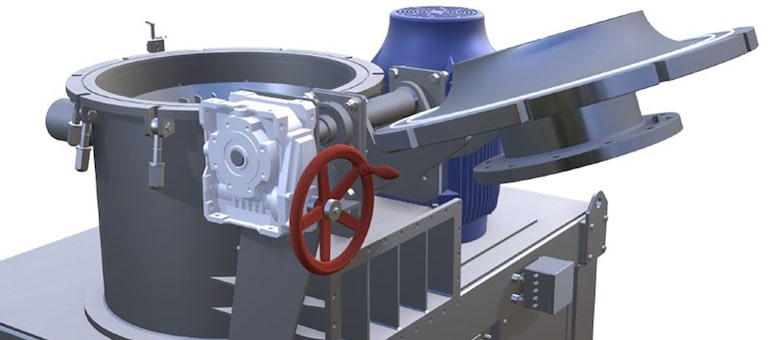

Clam-Shell design mill body for easy access to the grinding chamber. Suitable for batch processing or continuous operation the PPS Air Classifier range of Mills serve all industries that. Its durability reliability and precision are what make it one of the most popular industrial workhorses on the market.

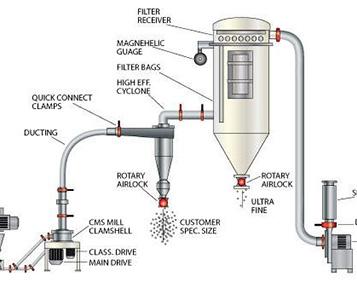

Air Classifying Mill. The air classifier is used to select the onsize material and return the oversize to the milling system. The Mikro ACM Air Classifying Mill is an air swept mechanical impact mill designed u0003to grind a wide range of materials down to D97 20 µm.

This mill incorporates several unique features that allow it to be quickly and easily disassembled and cleaned. The PPS Air Classifier Mill Range is manufactured in Carbon or Stainless Steel and can be designed to withstand 10 Bar PSR. Explosion-proof design is available.

We pursue the management tenet of Quality is remarkable Company is supreme Name is first and will sincerely create and share success with all clientele for Air Classifier Design Grain Mill Grinder Jet Mill Cost Classifier Machine Jet Vertical Mill Price. An Air Classifier Mill is used for milling and grinding heat-sensitive material and provides precise control over particle cut point selection by incorporating an internal air-classifying wheel and an independent drive. Brand ALPA is a manufacturer and supplier of Custom Air classifier mill of various types and a large-scale factory.

The ufg mill is normally operated in closed circuit grinding with a high efficiency air classifier. External air purged classifier rotor seal insuring clean topsize cuts. We bring for the clients Air Classifying Mill of exceptional quality at cost-effective price.

Mikro ACM-Easy Access Air Classifying Mill design. Grinds and Classifies down to D97 20 µm. The pro-ductair mixture is distributed uniformly by the guide shroud ring to the rotating ACM schematic AreA of ApplicAtion Mikro ACM classifier mills are distinguished by their compact design and intuitive.

The mill uses airflow to convey feed material to the mills grinding chamber segregate the material into fine and coarse fractions recirculates the coarse material for further grinding and moves the fine particles out of the millSimply put the intelligently engineered Air Classifier acts as a mini segregation factory. The PPS Air Classifier Mill Machine is a vertical grinding mill that incorporates an internal air classifying wheel with an independent drive. RSG Inc manufactures air classifiers ball mills and stirred media mills for the production of fine superfine and ultrafine powders for the mineral mining cement lime metal powder and chemical industries.

The productair mixture is distributed uniformly by the guide vane ring to the rotating classifier. The integrated dynamic classifier is cha-racteristic of the Mikro ACM. In addition PPS Air Classifier Mills benefit from flexibility of design allowing systems to be customized to fit into all types of physical layouts.

The compact design intuitive arrangement of its components and flexibility of the entire range still set it apart from other classifier mills. And to provide you with the most advanced process and design. Material Product Mill Material Food Ingredients Cane Sugar 20 Mesh 90 325 Mesh 12x Soya Flake 14 98 80 Mesh Milk Crumb 20 Mesh 99 400 Mesh.

Air Classifying Mill is used for separating dry materials into different particle size fractions by their size mass or shape also modify a particle size distributionWe have established a note worthy status among the Air Classifying Mill Manufacturers in India. Through the mill and routed along the guide vanes of the shroud ring. Pressure capable quick-release pipe connections.

Air classifiers are often used in closed circuit with grinding mills such as ball mills hammer mills roller mills or jet mills. They work by balancing the physical principles of centrifugal force drag force collision and gravity to generate a high-precision method of classifying particles according to size and density. All machines have the unique PPS design with either a single or double opening grinding chamber to facilitate easy cleaning and maintenance.

Air classifying Mill Air classifier Mill ACM can be designed for grinding hygroscopic heat sensitive. The unique airswept design allows for high production of ultrafine powders. RIECO Air Classifier Mill ACM is an air classifying mill with integrated grinding classifying conveying and collecting operations for achieving ultra-fine grinding up to 2 micron depending upon the nature of the product.

Specializes in fine powder processing technology. The product becomes entrained in the cooling conveying and classifying air drawn through the mill by the downstream fan and is routed along the guide vanes of the vane ring. Air Classifier FLITC Vertical Air Classifier.

It is commonly used for milling heat-sensitive material and provides precise control over particle cut point. At AVEKA CCE Technologies we design build and sell custom air classifiers for your milling needs. For dry materials of 100 mesh and smaller air classification provides the most effective and efficient means for separating a product from a feed stream for dedusting or for increasing productivity when used.

How Does A Pps Air Classifier Mill Work Kemutec

How Does A Pps Air Classifier Mill Work Kemutec

Pps Air Classifier Mills Kemutec

A Complete Guide To Purchasing An Air Classifier Aveka

Air Classifier Mills Solidswiki

Air Classifier Mill Machine Explained Bulkinside

0 comments

Post a Comment